PRODUCT

LH-65S LH-65D LH-75S LH-75D LH-90S LH-95D LH-115S LH-115D LH-130S LH-130D LH-150S LH-150D mechanical seal

LH type mechanical seal for Xiangyang 525 ZD/ZG heavy duty slurry pump

Mechanical seals are divided into single end manifold and double end manifold

Single-end face manifold type: There is only one pair of sealing joint faces, which are pre-assembled by the sealing manufacturer before leaving the factory. No customer adjustment is required, just assembling directly. Easy to install and simple to use. The cooling water pressure is controlled between 0.05-0.1MPa

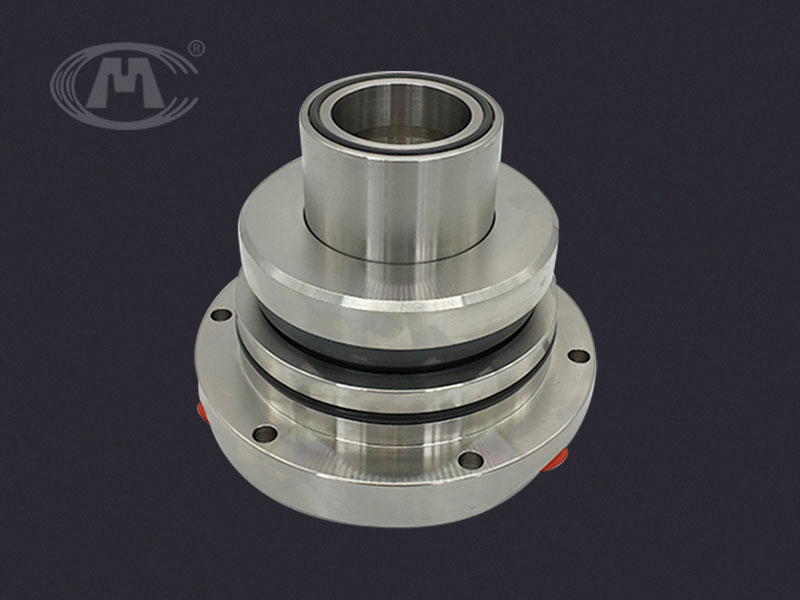

Single end face seal picture

Double-end-face container type: There are 2 pairs of sealing joint surfaces, which are pre-assembled by the sealing manufacturer when leaving the factory. No customer adjustment is required, just assembling directly. Easy to install and simple to use. The cooling water pressure is controlled between 0.05-0.1MPa

Double end face seal picture

The double end face generally refers to the exterior double end face, which is a derivative of the single end face exterior type (the single end face seal water side skeleton oil seal is changed to a set of tandem mechanical seals) to increase the service life

Structural features:

Single end face (double end face) cartridge mechanical seal. Easy to install and simple to use. Balance, arbitrary rotation.

The internal working length is short. The static ring compensation multiple springs are externally not in contact with the medium.

Applicable medium:

Medium containing high impurity content such as gypsum and lime slurry.

Working parameters:

Fixed content: ≤30%

Temperature: ≤280℃

Pressure: ≤2.5MPa

Shaft diameter: ≤200mm

Material parameters:

Body material: 316L or 2205, 2507, 1.4529

Seal ring material: SSiC or SiC

Rubber material: fluorine rubber or perfluoroether rubber

main application:

This type of mechanical seal is mainly used for flue gas desulfurization of coal-fired power generation, and is suitable for absorption tower slurry circulation pump, gypsum slurry pump, limestone slurry pump, and gypsum discharge pump. It can also be used for various types of slurry pumps to transport various media with particulate matter.

Common pump numbers are as follows:

40ZD-170 40ZG-190 40ZD-190 50ZD-330 65ZD-300 50ZG-460

50ZD-500 80ZG-420 80ZD-420 80ZD-360 100ZD-360 50ZG-500

50ZD-500 80ZG-520 80ZD-500 100ZG-500 100ZD-500 150ZG-500

150ZD-500 100ZG-570 100ZD-570 150ZG-600 150ZD-600 200ZG-600

200ZD-600 150ZG-650 150ZD-650 150ZG-700 150ZD-700 200ZG-650

200ZD-650 200ZG-700 200ZD-700 200ZG-750 200ZD-750 250ZG-750

250ZD-750 250ZG-650 250ZD-650 300ZG-700 300ZD-700 200ZD-850

200ZG-850 250ZG-850 250ZD-850 300ZD-900 250ZG-960 250ZD-960

300ZG-1000 300ZD-1000

Seal model:

LH-28S2-S/SV7 LH-45S2-S/SV7 LH-65S2-S/SV7 LH-75S2-S/SV7

LH-90S2-S/SV7 LH-115S2-S/SV7 LH-130S2-S/SV7 LH-150S2-S/SV7

LH-28D3-S/SV7 LH-45D3-S/SV7 LH-65D3-S/SV7 LH-75D3-S/SV7

LH-90D3-S/SV7 LH-115D3-S/SV7 LH-130D3-S/SV7 LH-150D3-S/SV7

Installation and use requirements:

1. The radial runout of the shaft of the equipment should not be greater than 0.04 mm, and the axial runout is not allowed to be greater than 0.1 mm;

2. The sealing cavity of the equipment should be kept clean during installation, the sealing parts should be cleaned, and the sealing end face should be intact to prevent impurities and dust from being brought into the sealing part;

3. It is strictly forbidden to knock or knock during the installation process, so as not to damage the mechanical seal due to friction and seal failure;

4. During installation, the surface in contact with the seal should be coated with a layer of clean mechanical oil for smooth installation;

5. When installing the static ring gland, the tightening screws must be evenly stressed to ensure that the end face of the static ring is perpendicular to the axis line;

6. Push the moving ring by hand after installation, which can make the moving ring move flexibly on the shaft and have certain flexibility;

7. Rotate the shaft by hand after installation, and the shaft should not feel light or heavy;

8. The equipment must be filled with medium before operation to prevent dry friction and seal failure;

Service hotline:0813-3202978

Working days: Monday to Saturday

Time:8:30-18:00

Tell:

0813-3202978

Email:

Consulting:

13890019297

Zigong Chuanmi Mechanical seal Co., LTD 蜀ICP备12011709号-1